Industrial extraction tank

Our industrial extraction tanks are well designed and widely used in pharmaceutical, biological, food and chemical industrial. Its main function is to extract valid and valuable ingredients from hemp, plants, herbs and the extraction of aromatic oil. Our industrial extraction tank supports customization to meet customers’ requirements and optimize production process to achieve higher efficiency and lower waste and cost. Our extraction tanks can be designed to be suitable for normal pressure, high pressure and vacuum production environment and fit for water and organic solvent extraction using thermal reflux and forced circulation technology etc and solvent recovery based on customers’ needs.

Structure features:

1. Meeting GMP standard and pressure vessel regulation to ensure safety. Fine polishing in both interior and exterior.

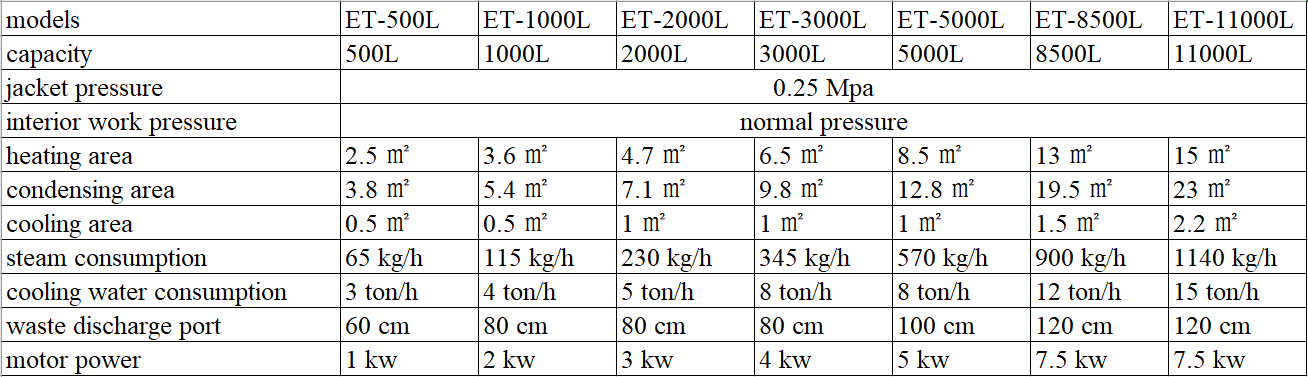

2. Main parts of equipment: tank body, foam eliminator, condenser, chiller, oil-water separator, filter etc.

3. Two heating/cooling methods for tank: Jacketed heat transfer and spiral tunnel. Liquid discharge port and steam/coolant inlet are usually designed on two sides of waste discharge port. Material inlet, exhaust, viewing and cleaning port and tubes are usually designed at the top of tank.

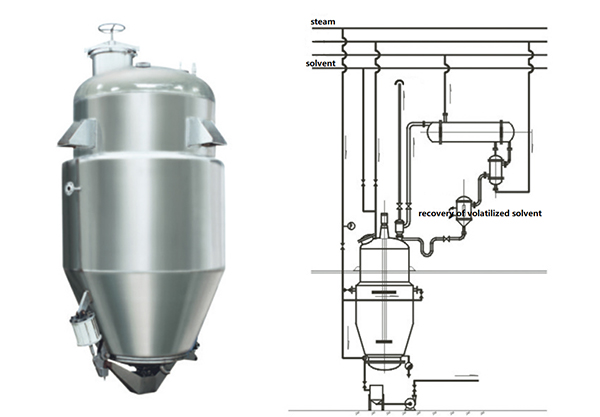

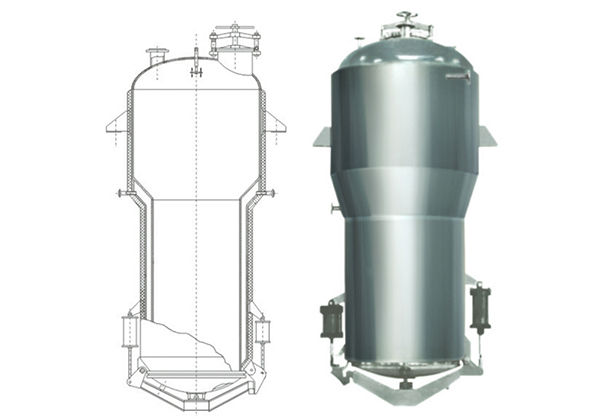

4. Tank shape: straight tank type, cone tank type, mushroom type, inverted cone type, slant cone type etc. Stirrer can be customized to fit for different types of tanks.

5. Able to enlarge filtration area if needed to increase production efficiency.

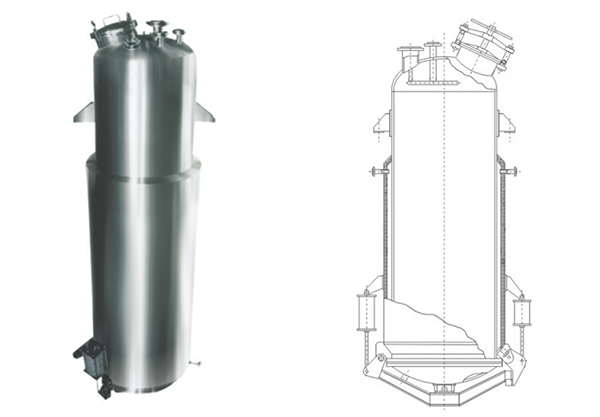

Models